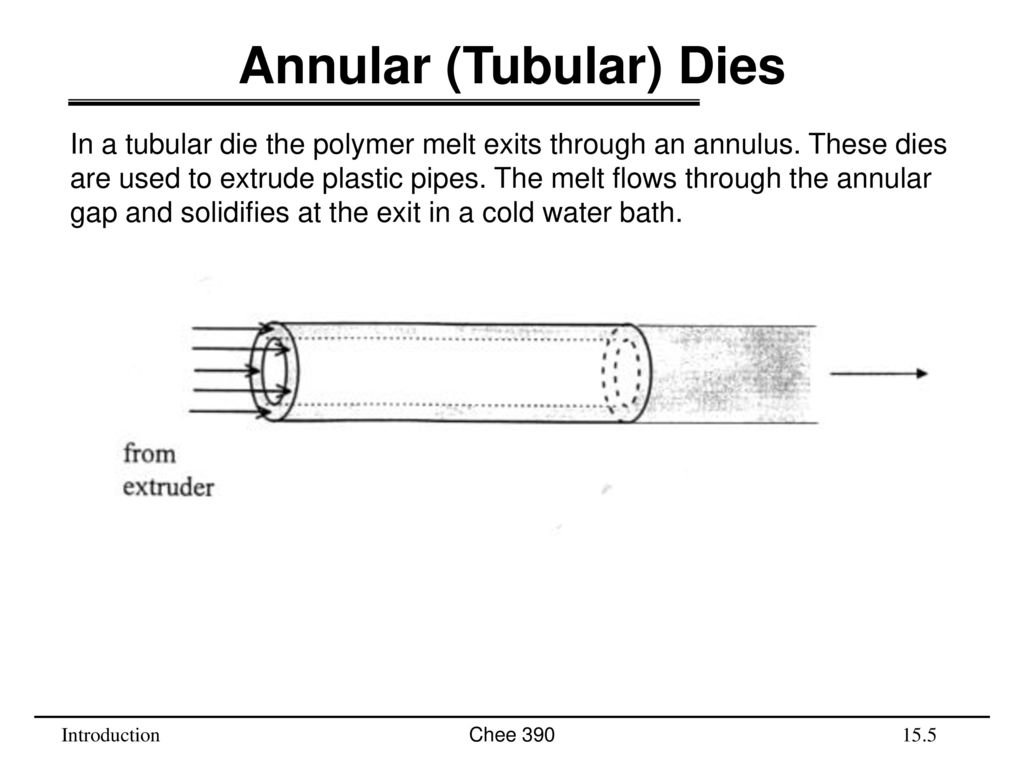

Influence of flow pattern development at die entrance and inside annular die on extrudate swell behavior of NR compound

CONTROL OF THE THICKNESS DISTRIBUTION OF BLOWN FILM BY CHANGING THE FLOW CHANNEL GAP OF THE DIE OVER THE CIRCUMFERENCE t

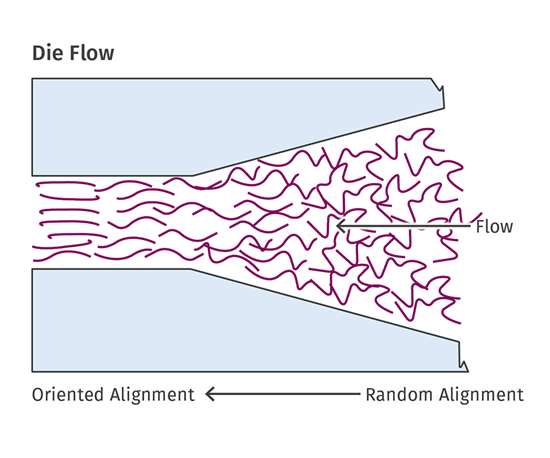

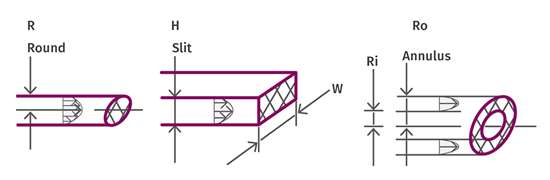

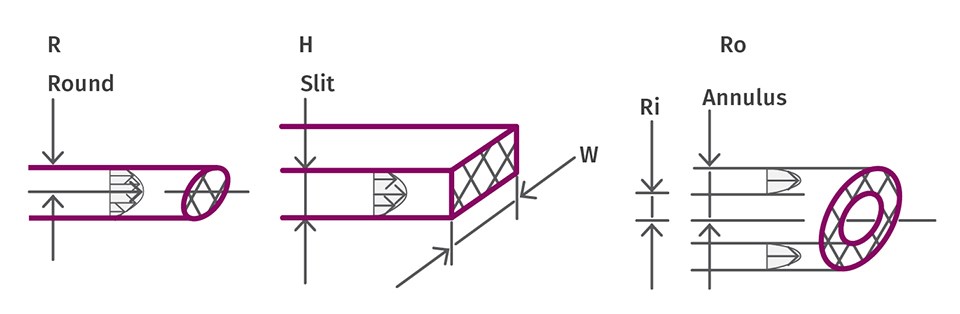

Flow visualization & extrudate swell behavior of natural rubber compound in annular die capillary rheometer

Influence of flow pattern development at die entrance and inside annular die on extrudate swell behavior of NR compound

CONTROL OF THE THICKNESS DISTRIBUTION OF BLOWN FILM BY CHANGING THE FLOW CHANNEL GAP OF THE DIE OVER THE CIRCUMFERENCE t

Flow curves of NR compound with and without addition of Titanium Oxide... | Download Scientific Diagram

EP0043271A1 - Method and apparatus for cooling film bubble of low strain hardening polymers - Google Patents

Flow visualization & extrudate swell behavior of natural rubber compound in annular die capillary rheometer